We help people in business improve: LeanLine Floor Design. Lean Layouts. Factory Organisation & Optimisation. We can help you improve processes. We can help you reduce costs…

We help people in business improve: Warehouse Organisation & Operation. Picking, Kitting, Kanban Organisation. We can help you organise inventory… We can help you improve cash flow…

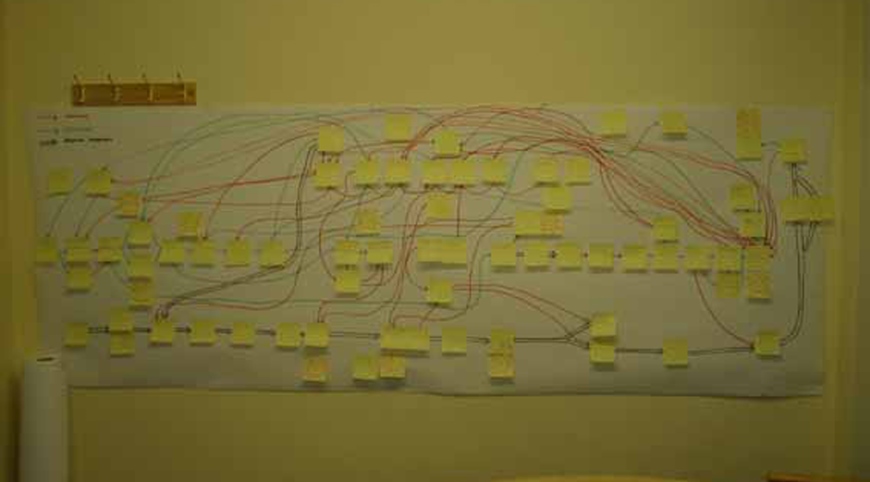

We can help you analyse the present. We can help you improve methods…. We can help you with cycle times.… We can help you reduce costs……. We can help you increase profits…

Process Improvement is about eliminating Non-Value Waste… Businesses “Don’t Plan To Fail… People in business Fail To Plan”... ABOUT US –>>

LEAN MANUFACTURING IMPROVEMENT

How to Get MORE Out of Your Business

For over 30 years we’ve designed and implemented business improvements.

We’ve generated for our clients between £50k and £2.0M per project…

Please Call – UK: 07300 788 486 or E-Mail

We can help you:-